|

|

We as a global society are leading the rest of the World in mass consumerism.

We as a global society are leading the rest of the World in mass consumerism. | Sail Power | AgOH Biocides | NWTC | Long Range EV's | Rare-Earth Recovery | F-S R&D Contact Center |

| This

is about Large Scale, Large Volume, Mass Spectrum Retrieval Systems

that can recover Rare-Earth Elements out of semiconductor e-wastes far

more efficiently than strip-mining entire mountain sides. The basics of this simple technology are described in the following white paper: R.E.R. White Paper. "This is not about Science. This is about the Conservation of Matter;

Conserving the last of the Planet’s Rare-Earth Resources, --down to the last atom." Please consider this: The US imports millions of tons of highly refined materials/minerals/products from the Far East in the form of Consumer Electronics every month that we pay rock bottom prices for; only to be exported back to them as toxic trash the very next month.   Consider

for every ton of dirt that is strip-mined, only a few ounces of the

Rare Earth Elements can be smelted down for use. Consider

for every ton of dirt that is strip-mined, only a few ounces of the

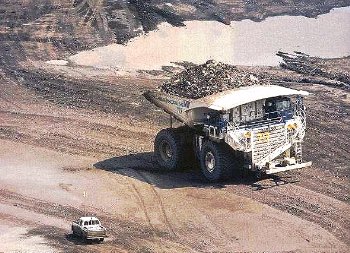

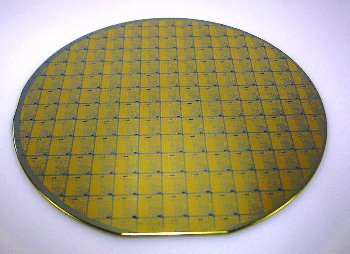

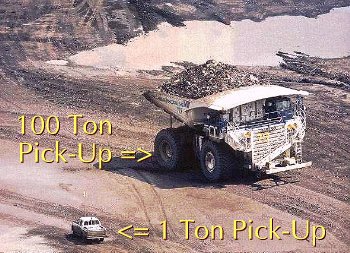

Rare Earth Elements can be smelted down for use. Now consider that for every truck load of raw dirt hauled out of a pit mine, there are six more truck loads of coal coming out of a much larger open pit coal mine that are needed to process that first truck load of dirt into something you call a Cell Phone.  1) The first truck load of coal is used up in strip mining the raw land for the minerals and hauling it to a foundry. 2) The second truck load of coal is used to smelt each ton of earth down to a few ounces of Rare-Earth Elements that are necessary in the manufacturing of semiconductors. 3) The third truck load of coal is used to power hot chambers that grow crystals out of silicon and other key minerals to be sliced into layers, or "wafers". 4) The fourth truck load of coal is used to run several types of semiconductor process machinery 24/7/365 days a years make enough Integrated Circuit Chips, IC's, to supply manufacturing demands. 5) The fifth truck load of coal is used to run the manufacturing floors 24/7/365; from plastic moldings, to printed circuitry, metal fabrication, final assembly, test, and packaging for approximately 100 million sell phones per day. 6) The sixth truck load of coal is used for the international shipping of these materials throughout the entire process, including the delivery of your "insta-web-product" directly to your front door for free in an environmentally friendly package, which was also printed in China with metal based inks. The next thing to consider is that for every ton of dead cell phones, there's upwards of fifty pounds each of the exact isotopes needed for next year's sell-phones, already purified.  There is also a rich source of Hydrogen, Oxygen, Carbon and other Rare Earth Elements being stored in post-consumer plastics, used solvents & oils, toxic waste dumps, and thousands of warehouses stuffed full of discarded chemical byproducts. If the Science Community can build a Hadron Collider, then it is quite easy to build a large Mass Spectrometer the size of a city block for a tenth the cost in half the time. Now we can collect Hydrogen, Oxygen, Carbon, and other pure elements directly from E-Waste and toxic trash piles.  Rare-Earth Recovery Systems are designed to extract these Rare-Earth Elements from everyday e-waste before they dissolve into our underground water systems. This would reduce the ground water poisons that affect most of the species in our food chain.  Moreover, these systems can supply a clean energy resource from our plastic trash piles, while drastically reducing the need for strip-mining new Land.  Using well-known technologies from both the Mass Spectrum Analysis Industry and the Semiconductor Manufacturing Industry, we could already be using these Rare-Earth Recovery machines. We could be dissolving old computers, reducing toxic waste-dumps, and strip-mining Super Fund Sites for precious raw materials in pure elemental form before we strip-mine more fresh Land to smelt down with yet more air polluting coal.  Moreover, this same technology can be modified to recover vast amounts of CO2

from the Earth's Atmosphere. We can mitigate Global Warming issues

directly, and return pure Oxygen to our breathable atmosphere as fast

as our missing Rain Forest used to. This can also supply a large

abundance of pure Carbon to a variety of Industries from tires, to

water filters, to lubricants, to structural fibers, to carbon

nano-tubes, to diamond coatings, and the rest. Moreover, this same technology can be modified to recover vast amounts of CO2

from the Earth's Atmosphere. We can mitigate Global Warming issues

directly, and return pure Oxygen to our breathable atmosphere as fast

as our missing Rain Forest used to. This can also supply a large

abundance of pure Carbon to a variety of Industries from tires, to

water filters, to lubricants, to structural fibers, to carbon

nano-tubes, to diamond coatings, and the rest.The secret to a Universal Solvent is Temperature. Every Atom, Element, and Chemical known on Earth has a Melting Temperature, an Evaporation Temperature, an Ionization Temperature, an Eichner Frequency, and an Ionization Potential. These five principles can be used in conjunction with proper machine timing to melt, evaporate, ionize, sort by atomic weight, and recycle a wide variety of toxic materials, chemicals, solvents, plastics, and most importantly, e-wastes; -just like any Mass Spectrometer can do, -only on a much larger scale.  Making wafers out of raw dirt is fancy enough, but that is not where the real magic happens. Making wafers out of raw dirt is fancy enough, but that is not where the real magic happens. The high powered physics needed to implant specific key elements and their isotopes into elegant, minuscule patterns within a silicon crystal lattice 24-36 layers deep is truly a feat of human accomplishment. What Humanity has not figured out, is how to use the very same physics that put a semiconductor chip together, to take it apart with the same atomic precision and intricacy that was used to put it together. "Why would you waste time doing that?" anyone would ask. Because if the world keeps making too many of these toxic IC's without a place to put them all when next year's models comes out, we as a world are going to run out of the Rare-Earth resources as well as the massive amount of energy that it takes to make these electronic gadgets, mostly for our daily convenience and entertainment.  Moreover, it costs about 5 times more coal burning global energy to smelt raw dirt than it takes to process e-waste in a closed-loop with the same physics that it was made with.  Otherwise, any day now, ...we will end up with too many of these....  Which will end up here....  -or end up here...  ...or here. We as Humanity will literally choke ourselves to death on a toxic, polluted, collapsing food chain within the next generation if we can not get a grip on the difference between a toxic trash pile and a Rare-Earth resource that could refuel the world economy.   Consider the scale at which things are happening with global consumption. Consider the scale at which things are happening with global consumption.On the left, one of these 1 Ton Cubes of highly compressed, post consumer toxic e-waste and scrap will fit in the back of the One Ton Pick-Up on the right. What you may not realize is that the 1 Ton Cube of reputed waste on the left has 50-100 times the mineral content and Rare-Earth density as that 100 Ton Pick-Up full of plain dirt has on the right. And more importantly, it only takes one truck load of coal to process an entire 100 Ton truck load of these 1 Ton Cubes. Think about that for a moment. Could there be some return on investment in refining our toxic e-waste and consumer trash on the mass atomic scale; rather than dumping it all on the bottom of the ocean, letting these rare resources rot away and poison the rest of the planet's food chain? Could there be a global financial benefit here?  Using well-known technologies from both the Mass

Spectrum Analysis Industry and the Semiconductor Manufacturing

Industry, we could already be using these Rare-Earth Recovery machines. Using well-known technologies from both the Mass

Spectrum Analysis Industry and the Semiconductor Manufacturing

Industry, we could already be using these Rare-Earth Recovery machines.We could be dissolving old computers, reducing toxic waste-dumps, and strip-mining Super Fund Sites for precious raw materials in pure elemental form before we strip-mine more fresh Land to smelt down with yet more air polluting coal. Using the same technologies that put IC's together, can be used to take them apart, atom by atom; to be put back together for next year's disposable products, never to enter a landfill again. Now, the Mining Companies can strip-mine the overflowing garbage dumps and burgeoning E-waste warehouses for the Rare Earth Elements that are used in today’s hi-tech electronic manufacturing. The basics of this simple technology are described in the following white paper: R.E.R. White Paper. We, as one world, need to start building this type of machinery and start dissolving all the Super Fund Sites, toxic land fills, obsolete computers, cell phone dumps, and scrubbing atmospheric CO2. We as Humanity, need to learn how to recoup pure Hydrogen, Oxygen, Carbon, Silicon, Gold, and other precious Rare-Earth materials from our own e-waste before we strip-mine any more fresh Land, -or send it back to China as toxic trash that just e more worldwide pollution. |

| Sail Power | AgOH Biocides | NWTC | Long Range EV's | Rare-Earth Recovery | F-S R&D Contact Center |

|

|

|

| FUTURE-SPARK | ||

| Saving the last of this Rare Earth, One Atom at a Time. |